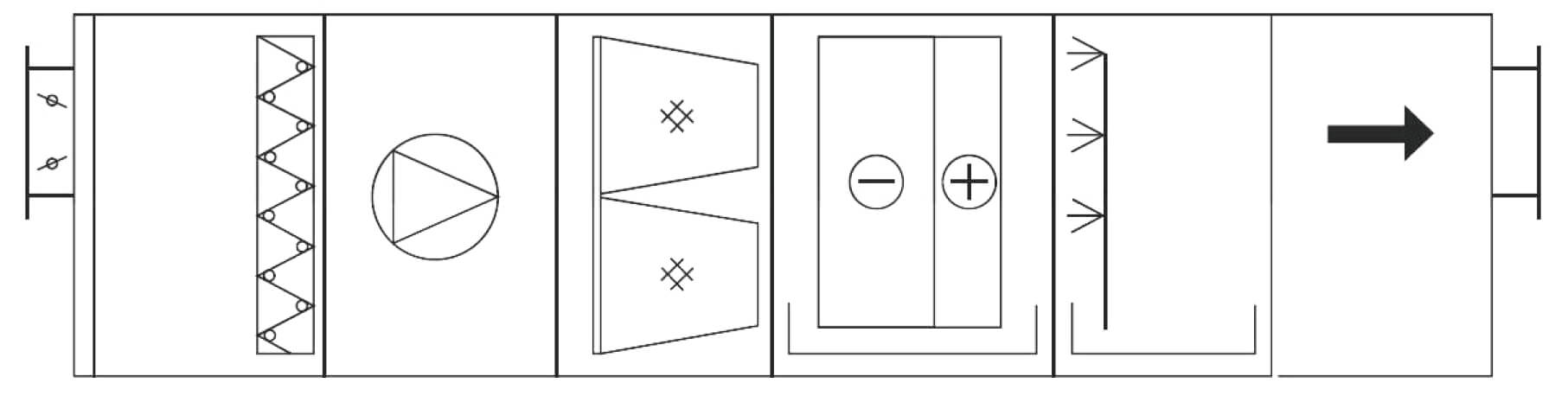

Medical Purificatory Modular Air Handling Unit is Amrta’s latest product with low air leakage ratio, high mechanical strength in terms of special requirements of operating clean room and other clean rooms in the field of medical treatment, chemical, food. It can efficiently control transmission of bacteria and spread of disease. Various high performance parts are exclusively equipped.

The Medical Purificatory Modular Air Handling Unit has two series: one modular air handling unit with cooling coil for water and other with cooling coil for refrigerant.

Medical Purificatory Modular Air Handling Unit is used for the clean room in medicine field. Its air conditioning system and equipment must apply special device to meet the requirement; there are some following features compared with normal air handling unit:

Low Air Leakage Ratio, High Mechanical Strength, Smooth Internal Surface

The frame adopts patented air leakage proof design, embedded groove making foam materials connect both0 internal and external panels tightly.

The foam material is high density polyurethane to make sure the strength of the panel.

Air leakage proof seal + bolt and nut, improving the seal between panels.

The internal panel is made of stainless steel with smooth surface to make sure there is no dust and no rust.

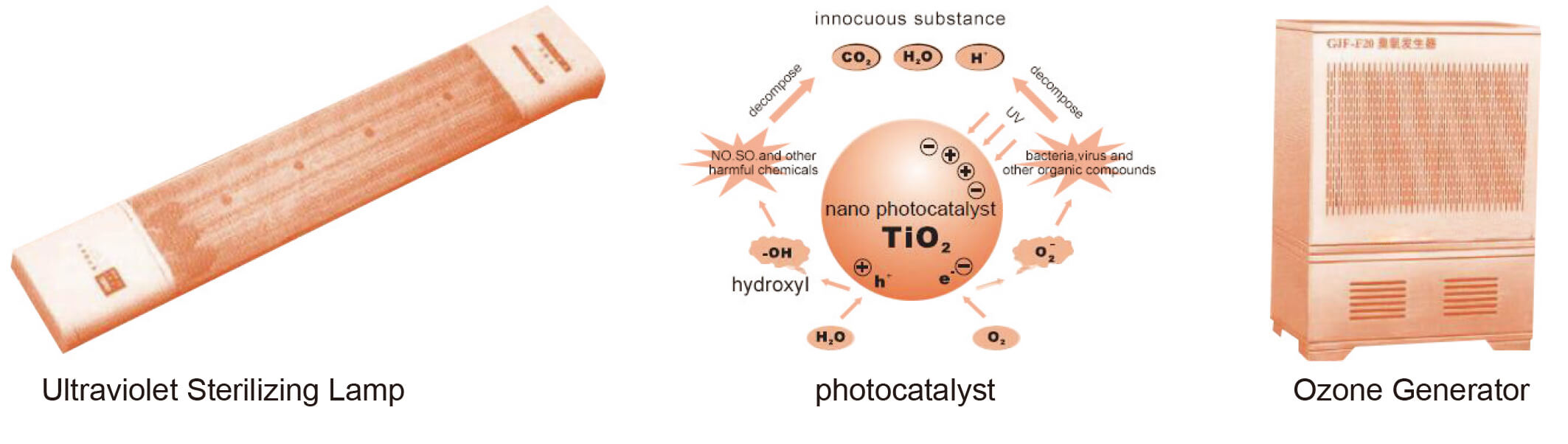

High Efficient Sterilization

The internal panel of the casing, condensing drainage tray and coil frame are all made of stainless steel. The heat exchanger is made of hydrophilic aluminum fan or copper fin to prevent bacteria.

Stainless tilt big drainage tray design make sure the internal of the unit does not remain water and breed the bacteria.

The unit is equipped with ultraviolet sterilizing lamp, photocatalyst, ozone generator and etc, effectively killing the bacteria and sterilizing, therefore improving the air quality.

The unit is also equipped with electronic purification device adopting advanced electrostatic precipitation technology, thus totally preventing breed and transmission of bacteria and virus and protecting from infection.

Advanced Internal Equipment

● Direct Driven and No Volute Frequency Conversion Fan

Using authoritative certificate and high efficient no volute frequency conversion fan with high transfer efficiency, no belt wear and stable operation. Meanwhile, the no volute fan is open-type structure and convenient to maintenance and clean, especially applied to the clear room.

● Naked Tube Heater

The heat exchanger pipe of the heater is made of stainless steel, smooth surface, without spiral fin, preventing accumulation of dust and breeding of bacteria.

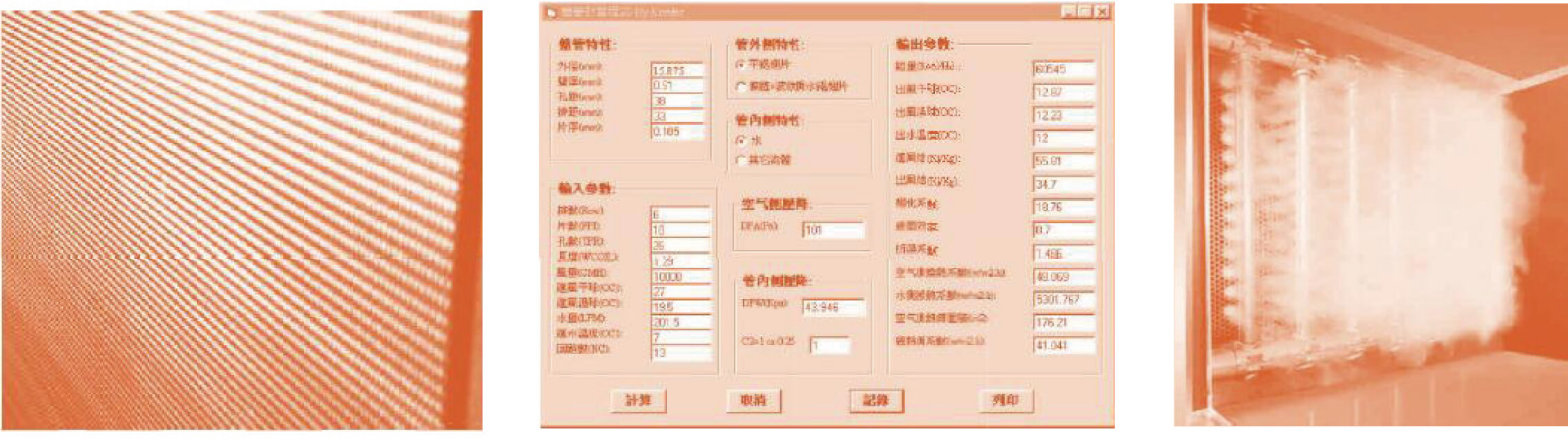

● Flexible and high-efficient antibacterial heat exchanger

The heat exchanger is designed by special computer auxiliary software, whose performance strictly meets the requirement of national standard of clean room. Hydrophilic aluminum fin or copper fin is applied, thus avoiding the air through the coil to take the condensing water covering on the surface of coil away. Meanwhile it also can prevent the breeding of bacteria.

Amrta provides coils with various specifications to meet different requirements of different customers. (different pitch of fins, various fin type, various copper tube diameters and materials for water collecting pipe.)

● Steam-type Humidifier

The unit uses electrode and dry steam to humidify, avoiding the humidified circumstance to keep from the breeding of bacteria.

High Quality Filter

The unit can use various filters with different degrees to meet customer’s requirements, thus optimizing its performance.

Filter is designed with special structure which is of high trapping efficiency and large volume. And it is easy to clean and change.

Both plate filter and bag filter are put in the same frame to minimize the length of casing greatly.

The filters from different manufacturers can be installed in the general fixed frame for filter. Frame galvanized and sprayed on the surface improves its anti-corrosion capacity. The surface of the metal plate is smooth enough without any sharp burr; the filter is near one by one and fixed by nuts, making it good airtight.

Optimized Design

Fan placed in the front make sure the unit is under positive pressure to prevent the outside air from leaking, which will pollute the clear air in the unit. And the condensate water can be drained because of positive pressure.

Areas where can produce water, such as filter protector placed in the front, heat exchanger, protect it from breeding of bacteria.

* Please leave your message!We will send detail technical info and quotation to you!